Home / solution

HZSS evaporator will provide a good and stable boiling process, when the temperature difference between refrigeration and second liquid is little. A low temperature difference means that a higher pressure may be corresponding to a higher evaporation temperature. Reducing the pressure difference between the low-pressure side (evaporator) and the high-pressure side (condenser) can reduce the energy consumption in the compressor. High evaporation pressure can also increase the density of refrigerant gas. Therefore, for each stroke, the compressor will carry more refrigerants through the system. Lower power consumption and higher cooling capacity will increase overall system efficiency (COP).

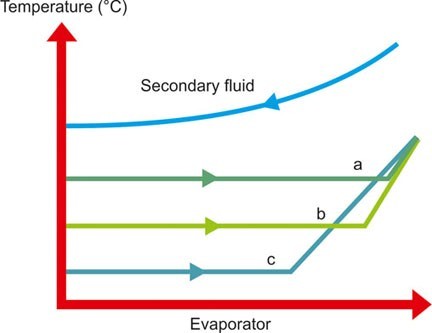

In the evaporator, the evaporation process occupies most of the heat transfer area. Although overheating accounts for only 5% of total heat absorption, the gas heating process usually accounts for 10-25% of the total heat transfer area.

The above diagram shows the overheating effect in the evaporator. Slightly overheat (a), there are more heat transfer surfaces for evaporation refrigerants. The results can improve evaporation temperature and system efficiency (COP).

On the other hand, if the evaporator is not stable, it will require a higher overheating (c), which will reduce the evaporation temperature and system efficiency (COP).

Heat is transferred from the refrigerant to the water cooled circuit and then used to heat the water. Heat through gas cooling, condensation, and supercooled liquid refrigerant to transfer, by increasing the water temperature, make its close to even more than condensation temperature, condenser temperature difference between inlet and outlet has been fully utilized.

The minimum temperature difference between the refrigerant in the countercurrent condenser and the secondary fluid (differential value) usually occurs at the starting point of the condensing process, i.e., point (b).

This is especially sensitive in the heat pump condenser, because the temperature difference between the condensing temperature and the secondary fluid temperature is very small (temperature close). Severe cooling may result in instability and local condensation risk. The condensing performance of HZSS heat exchanger is tested and verified. The temperature difference between the condensing temperature and the outlet temperature can be reduced to zero or below.

1. CO2 coaxial heat exchanger’ max. running temperature can be 135℃,and max. running pressure can be 14MPa.

2. CO2 coaxial heat exchanger can be used for CO2 transcritical cycle as cooler, evaporator, heat regenerator or oil cooler.

For CO2 transcritical cycle, the cycle efficiency is mainly affected by the outlet temperature and exhaust pressure of the CO2 side of the gas cooler when the evaporation temperature is certain. The temperature of CO2 that come out from gas cooler is lower, that means the temperature difference between CO2 outlet and water inlet is little, and the COP of the system will be higher.

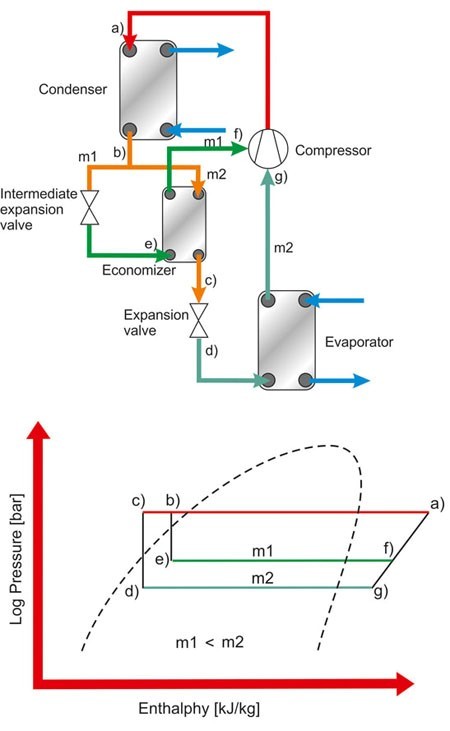

Some (usually 10-20%) refrigerants can be vaporized above evaporator's evaporation temperature, while significantly increasing the over-cooling performance of residual cooling fluids.

The economizer provides the system with two advantages:

1. Improve the COP of the system by increasing the over-cooling performance of the economic unit.

2. The refrigeration come out from evaporative side can reduce the compressor temperature.

These two factors increase the compressor performance by about 10% and provide a larger operating range for the compressor. Heat pumps can get higher seasonal COP, even if the heat pump is not heated by an auxiliary power, and can be run at very low ambient temperatures.