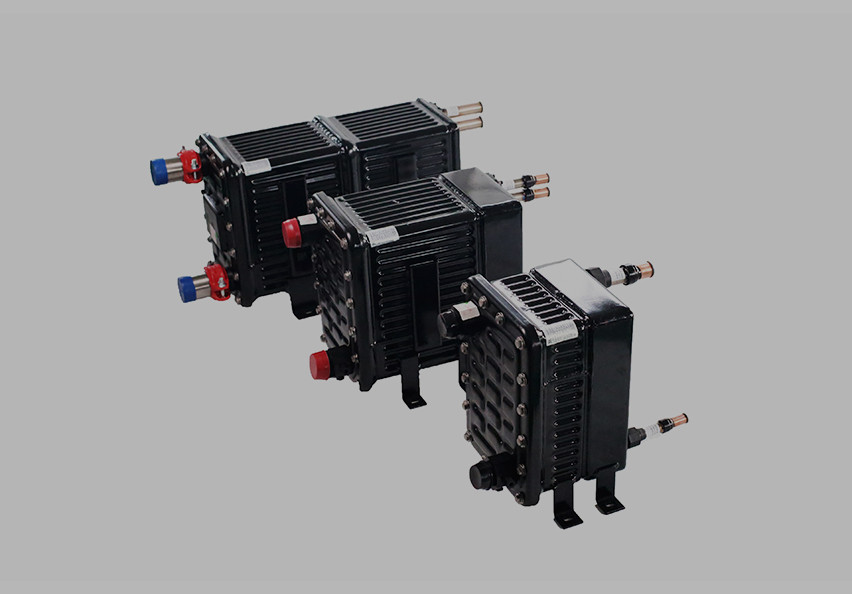

HZSS high quality tube in tube coaxial coil heat exchanger double pipe copper

HZSS high quality tube in tube coaxial coil heat exchanger double pipe copper

| Categories | Coaxial coil heat exchanger |

|---|---|

| Brand | SS coaxial coils |

| Model | SS-0125TT |

| Type | double cpper pipe |

| Color | Black |

| Tube material | cooper |

| FOB port | Shanghai/Ningbo |

| Terms of Payment | L/C |

| Update Time | Nov 21,2024 |

(1) Anti freezing

Water is not easy to get frozen because water is in a turbulence state as flow in the spiral groove inner tube at low speed. And the special spiral groove sturcture of inner tube makes the inner tube has a ability of flexibility, so it will not risk of frost crack.

(2) Self cleaning, no block

Fluid flow helically to scour the surface, so the coaxial heat exchanger has a bility of self cleaning. And the coaxial heat excahnger's performance is stable and has less attenuation. The sectional area of water passway is bigger so it allowed silt, fiber of big diameter to get through without get blocked. The passeay of water is clean because spiral grooves inner tube makes water flow in turbulence state that will clean the surface.

(3) Less welding points, higher pressure stand, more reliable

Because sipiral coaxial heat exchanger has few welding points with easy processing, the welding quality is easy to control. And it has little risk of leakage that may cause by prolonged vibration, pressure fluctuation, cold and heat alternation.

(4)High efficiency

Spiral grooved structure can have the effect of strengthening heat transfer on both sides. Both the axial flow of fluid in the tube and the screw rotating flow will exacerbated fluid mixing near the wall, which will enhance the turbulence intensity, increased heat transfer coefficient.

(5)Enhanced heat exchanging

① There are net dentation that will enlarge the contact area of fluid and inner tube surface.

② Net dentation can highten the turbulence and increase the Reynolds Number, so it will decline the thick of boundary layer of fluid.

As a consuquence, heat transfer coefficient is higher, heat transfer amount in 1 unit volume is more and heat transfer performance is much better.

(6) Long serve life

When the refrigeration system in practice, due to temperature fluctuation, start-stop cycle, heat pump defrost, expansion valve regulation and other factors, internal pressure is frequently alternating condition. Under the constant vibration and pressure changes, the spiral coaxial heat exchanger is much more capable of resisting pressure shock and pressure shock than the plate heat exchanger, so it can adapt to the complexity of the actual working conditions.

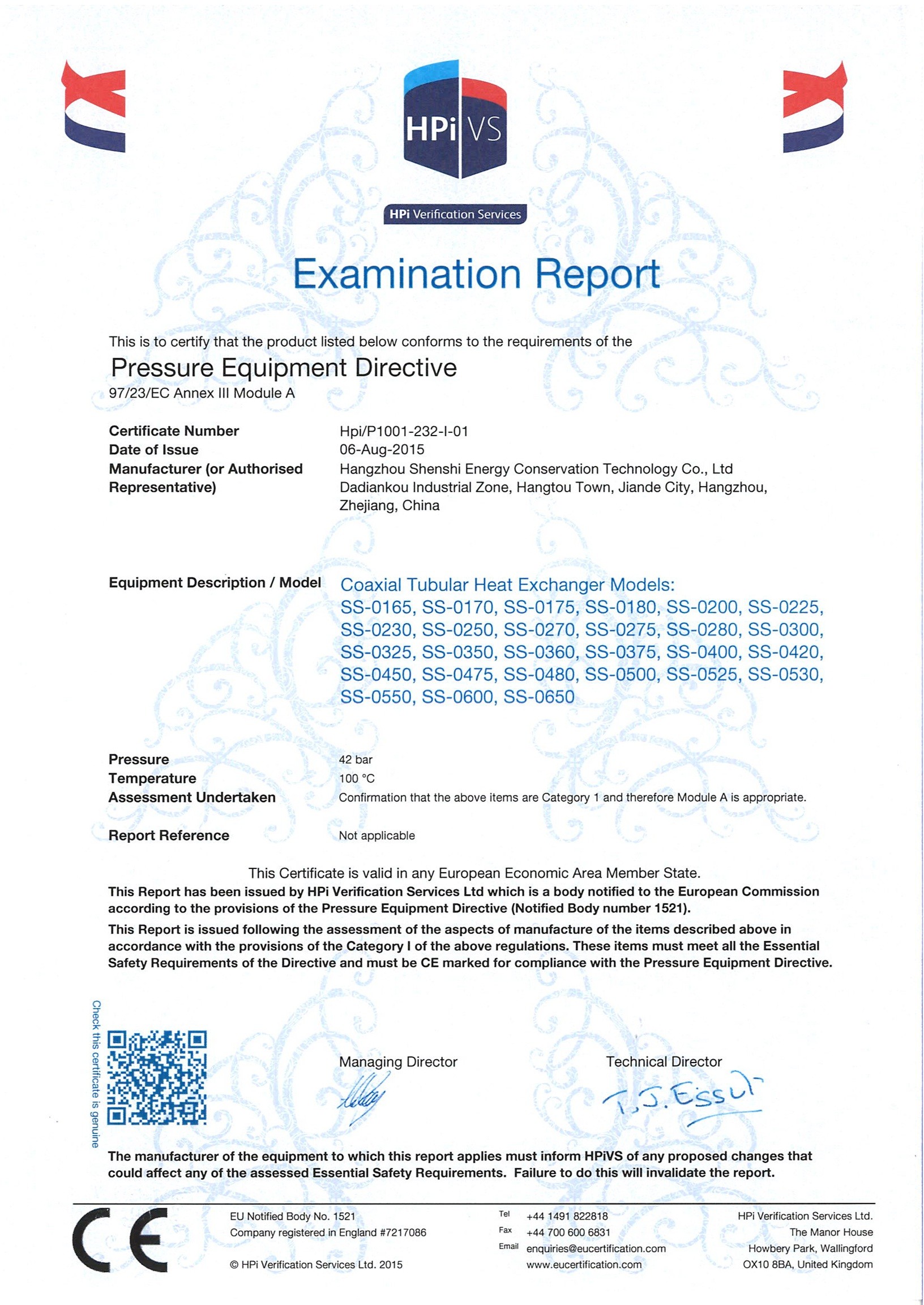

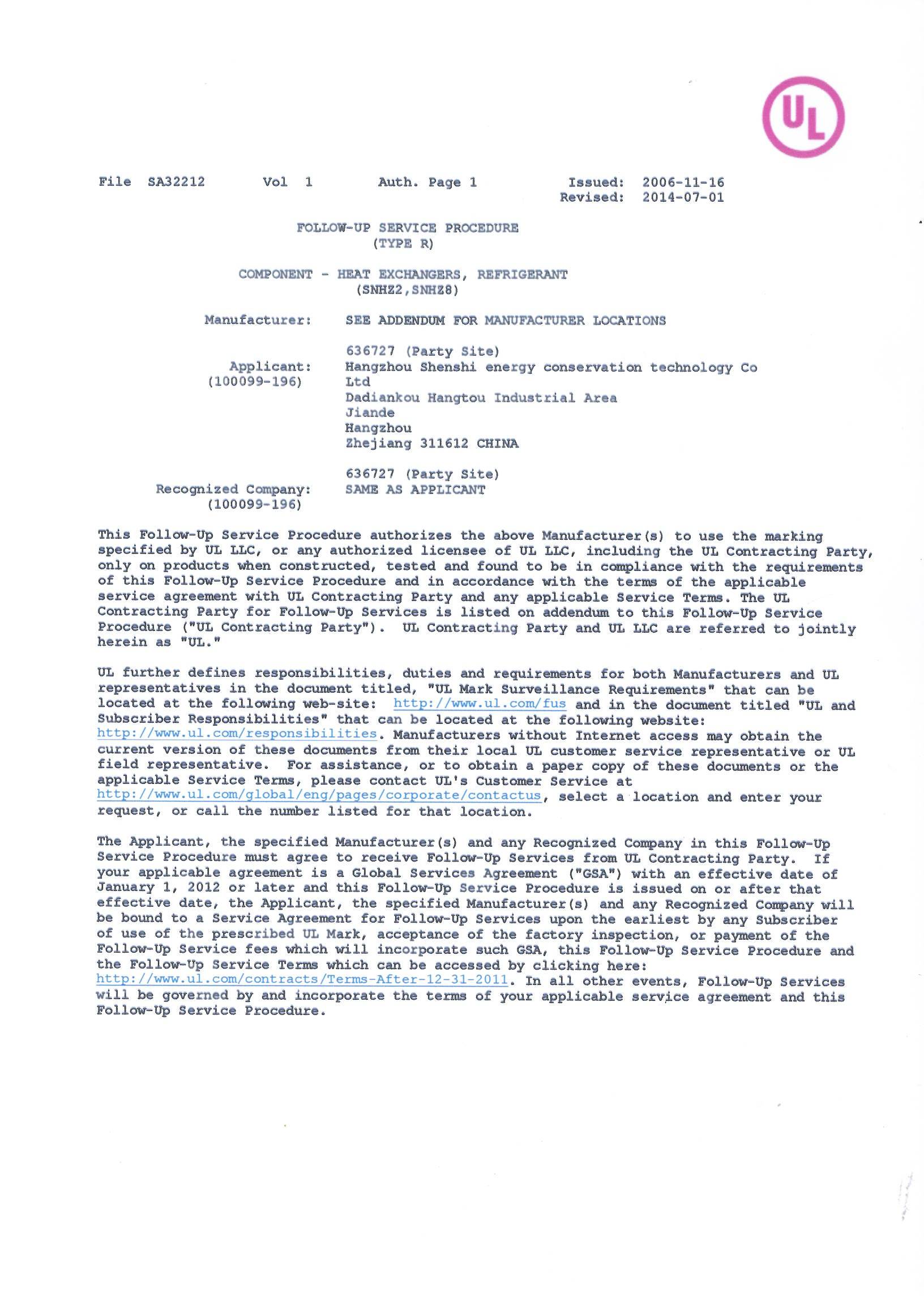

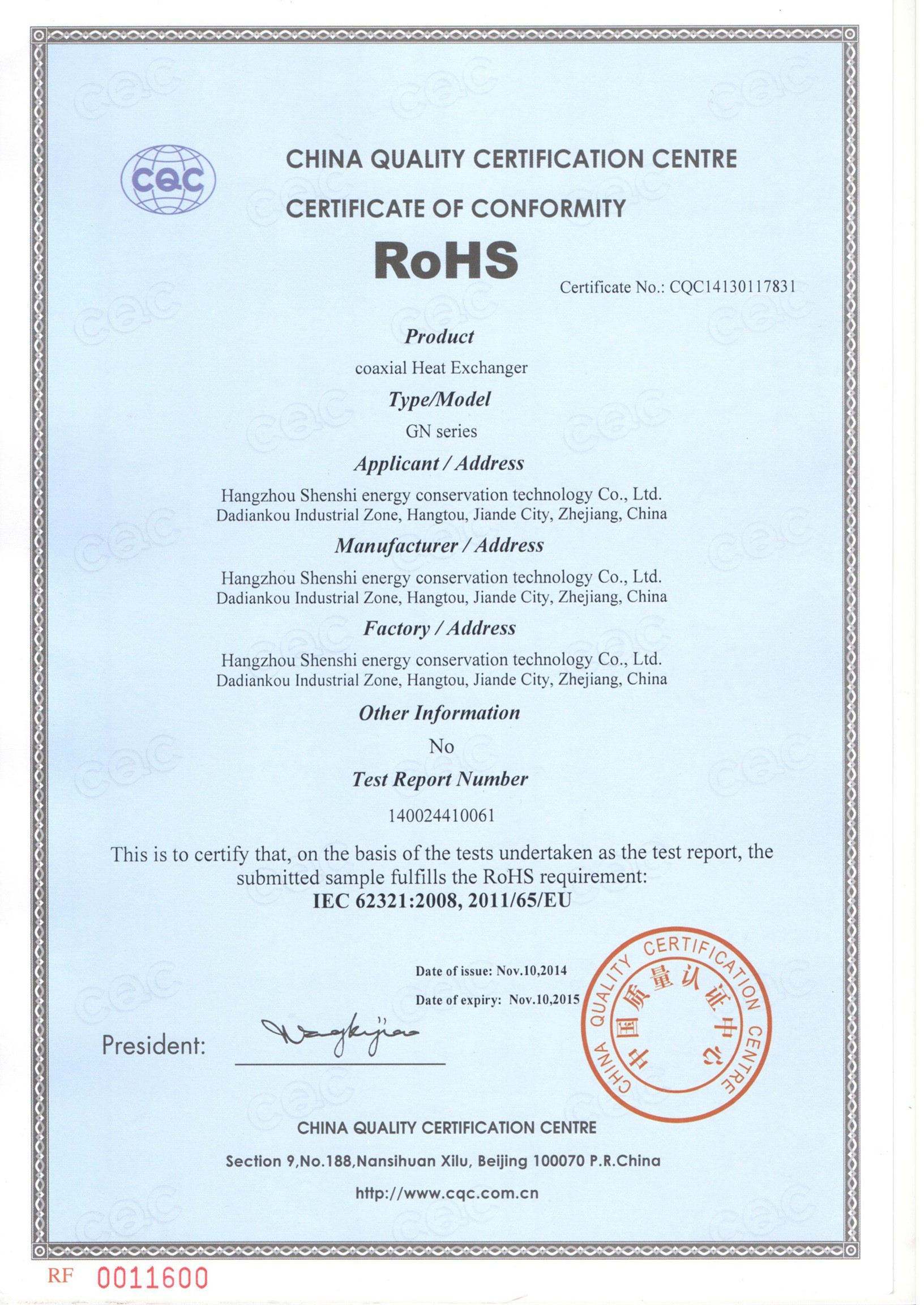

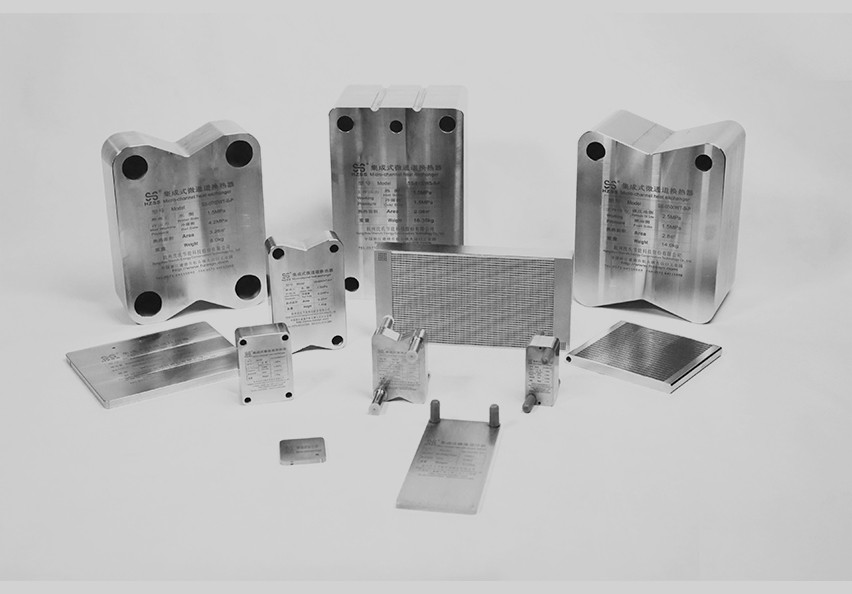

Hangzhou Shenshi Energy Conservation Technology Co., Ltd.(HZSS) was set up in the year of 2005 (the original name was Hangzhou Shenshi Heat Exchanger Co., Ltd.), and now located in Hangzhou Jiande, Zhejiang Province, China. HZSS is a professional coaxial heat exchanger manufacturer, and owner of the global-leading technology of integrated micro-channel heat exchanger and small climate system. HZSS focus on production and marketing and innovation of high efficiency and energy saving heat exchangers.

1.How to choose a match heat exchanger?

Pls fill in our Techology Selection Sheet, our engineer will recommend a match model to you.

2.If possible to customize?How to do?

Yes, We can supply OMD service.

We can maufacture heat exchanger according to customer's drawings.

Or we draw papers based on customer's requirements, manufacture after client confirm.

3.How long is the delivery time?

10 to 15 days for regular models, or 25 to 30 days for customized models.

4.How to packing?

Paper box and plywood pallet, or plywood case for heavy weight products.

Individual or multiple pieces per package base on weight and dimension.

5.How to pay?

In general by T/T and L/C at sight, OA is available for large quantity purchase order and long-term cooperation.

6.How to get sample?

Anything while the sample cost and freight is paid.

7.How many is MOQ?

Over 20 pieces.

8.How long is warranty?

The warranty is 1 year, but lifelong technical support and service.

Welcome to inquiry.

Tel:15656540867

E-mail:gjb9@hzssjn.com

Linkedin:Rachèle Guo

- Name

- Tel

- *Title

- *Content