R&D Innovation

Research And Development Center

Jiande R & D Center

HZSS Vision

With scientific and technological innovation as the leading, become the world's first-class fluid heat exchange solution service provider

Collaborate with Experts

Work with our experienced engineers to access leading equipment and exceptional technical expertise and application knowledge.

- Established Provincial Enterprise Research Institute in Zhejiang

- Collaborations with universities (Tsinghua University)

- Decades of industry expertise

Innovate Through Testing

We will work together to refine your solutions and validate performance through benchmarking, development, improvement, and testing.

- National Torch Program Project

- Advanced laboratories

Accelerate Your Business

Reduce costs, shorten development times, and bring your business to market quickly in an environmentally friendly way, staying ahead of the competition.

- Faster time to market

- Meet future low-carbon applications

- Achieve sustainability

R&d Qualification

Holds 107 Patents

- 28

Invention Patents

- 2

PED International Patents

- 2

Software Copyrights

11 Innovative Product Identifications

- 6

Internationally Advanced

- 5

Domestically Leading

Wei Zhiyuan Laboratory

Analytical R&D Lab

We have an independent laboratory of about 80 square meters, equipped with Agilent gas chromatographs, WATERS liquid chromatographs, Shimadzu UV spectrophotometers, and other testing instruments. This setup allows us to perform routine analysis and testing for ongoing projects. We also collaborate with Zhejiang University, Zhejiang University of Technology, Zhejiang Sci-Tech University, and China Jiliang University for advanced analysis and testing, such as NMR and mass spectrometry, providing efficient and reliable results for process development.

Synthesis R&D Lab

We have a laboratory of about 400 square meters, equipped with 18 fume hoods and 3 floor-standing fume hoods. The lab also features over 10 microreactor systems (with hold-up volumes including 8.2 ml and 20 ml; materials include silicon carbide, Hastelloy C, 316L, titanium, etc.), various plunger pumps and diaphragm pumps of different materials and specifications, and standard equipment like BUCHI rotary evaporators. This setup allows simultaneous process development, optimization, and pilot-scale experiments for multiple projects. Currently, the lab collaborates with Zhejiang Pharmaceutical Co., Ltd., Zhejiang Yefeng Pharmaceutical Co., Ltd., and Hangzhou Rohto Technology Co., Ltd., among others.

Research And Development Technology

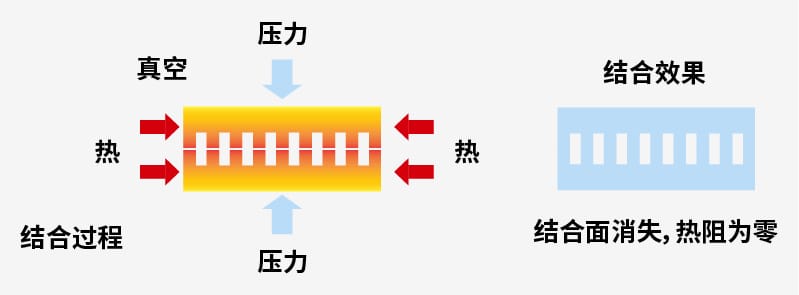

Diffusion Bonding Technology

The principle involves stacking multiple layers of metal sheets of varying thickness, processing them into flow channels and shapes, and then applying appropriate pressure and temperature in a vacuum to fully bond the metal surfaces. Heat exchanger cores made using diffusion bonding technology have advantages such as no joints, no welds, and no potential failure points of any other type. The strength of the bonded material can exceed 95% of the parent material, ensuring excellent product performance.

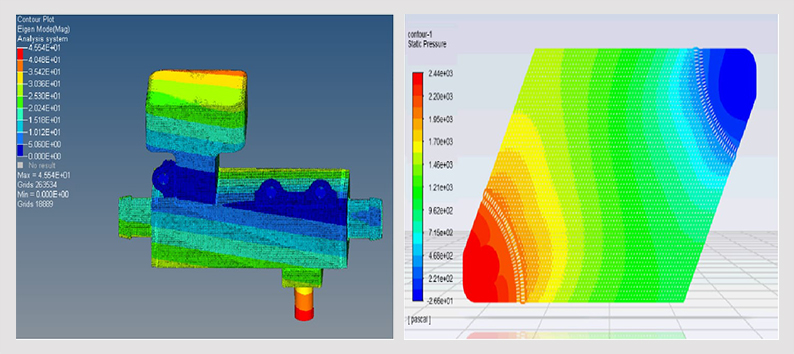

Design Calculations

Based on years of experience in calculations, simulation modeling, and experimental testing for microchannel and plate-fin products, we have developed calculation formulas and correction factors to ensure design accuracy. This has led to the creation of our own unique heat exchanger product design methods, allowing us to provide feasible design solutions based on different environments, appearances, and heat exchange requirements.