Microreactor

- Technical

- Working

- Products

- Related Industry

- Case

- Service

- Download

Technical Characteristics

Small Size

High Efficiency Heat Transfer

High Pressure Resistance

Strong Reliability

Wide Applications

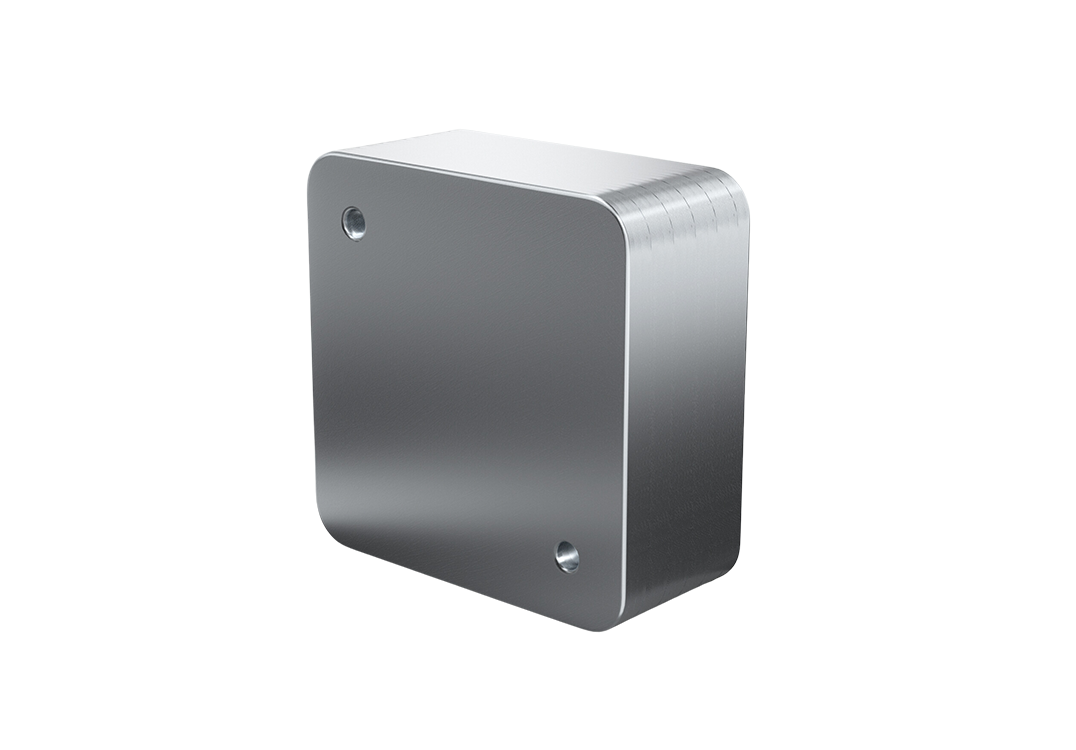

Products

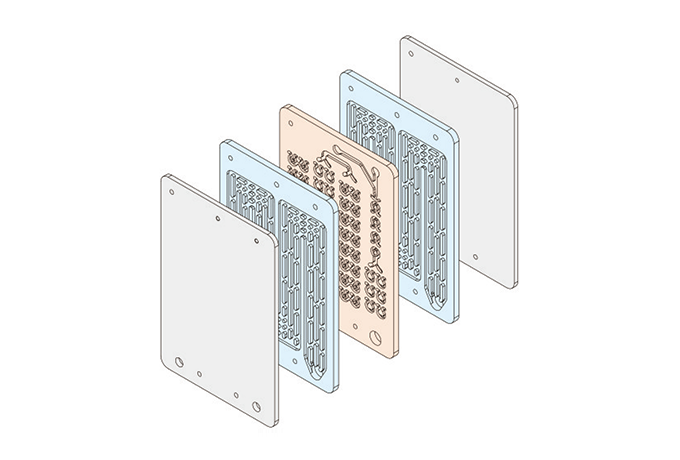

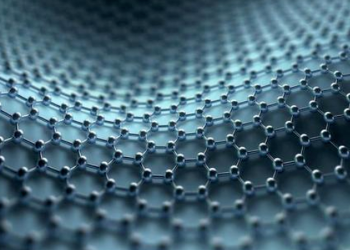

A miniaturized reaction device integrating multiple microchannel reaction units.

Achieves efficient mixing and heat transfer through rotational flow inside the spiral tube.

Utilizes fluid dynamics effects within microchannels to achieve rapid and uniform mixing.

A miniaturized reaction device suitable for laboratory research.

An integrated reaction device combining microreactor technology with continuous flow technology.

Industry

Used in drug synthesis, catalytic reactions, crystal engineering, purification, and separation, offering advantages such as high efficiency, speed, precision, and strong controllability. Accelerates new drug development and improves production efficiency.

Features high heat and mass transfer efficiency, optimizing key processes such as heavy oil cracking. Supports the development of new processes and promotes continuous, efficient, and low-cost petrochemical production.

Enhances synthesis efficiency and product quality, accelerates the development of new pesticides, and promotes continuous and automated pesticide production while reducing costs.

Optimizes the dye synthesis process, improves color mixing uniformity, supports new dye development, and enhances the continuity and efficiency of dye production.

Efficiently synthesizes complex fragrance components, precisely adjusts fragrance ratios, accelerates new product development, and achieves high automation in production processes.

Facilitates the synthesis of nanomaterials, enhances uniform mixing of material components, supports rapid development of new materials, and promotes continuous and large-scale production of new materials.

Service

Diverse Material Options

Materials such as 316L, duplex steel, Hastelloy C276, TA10, Zr, and silicon carbide can be selected according to actual working conditions.

Customized Core Components

Includes microchannel reactors, microchannel mixers, microchannel heat exchangers, and tubular reactors, among other equipment.

Flexible Application Forms

Various flow channel combinations available, with options for multi-stream feed and zonal temperature control. Can be used individually or in multiple series configurations.

Standardized Connection Sizes

Standard imperial or metric interfaces are available, with custom options also offered, facilitating easy connection with other equipment systems.

Seamless Industrial Integration

Seamless integration from laboratory development and pilot testing to full-scale industrial production, with minimal scale-up effects, making industrialization easier to achieve.

Diverse Service Fields

Provides specialized design and customization services for clients in various fields, fully meeting their diverse needs.

Quality Assurance

The product quality guarantee period is 18 months after the contract is signed or one year after the product is put into use.

Download

Product Manual

- Microcontinuous flow product sample