Withstand Voltage

4-15MPa

4-15MPa

-253~1000℃

1*10-9Pa·m3/s

The secondary welding has no adverse effect on the core weld of diffusion welding

Chlorine, acid, base, ammonia, mercury, etc

Titanium, titanium alloy, stainless steel, superalloy, copper alloy, etc

The fuel reformer mixes the fuel with water vapor, heats it, and feeds it into the anode of the system.

Heat is exchanged between water and high-temperature exhaust gases to produce a mixture of water vapor and fuel gas.

Reduce the temperature of CO₂ to its required operating range.

It is used to capture and utilize excess heat generated during the operation of nuclear power plants, helping to improve the overall efficiency of nuclear power plants.

The air heater is to heat the air that passes into the hydrogen production system to reach the reaction temperature.

The steam generator turns the raw water into a gas, which enters the SOEC reactor and produces hydrogen.

Hydrogen reformer produces hydrogen by reforming methanol, water and other fuels for heat exchange.

Hydrogen liquefaction plate-fin heat exchanger is a heat exchanger in which hydrogen and nitrogen gases are exchanged to cool them to liquid state

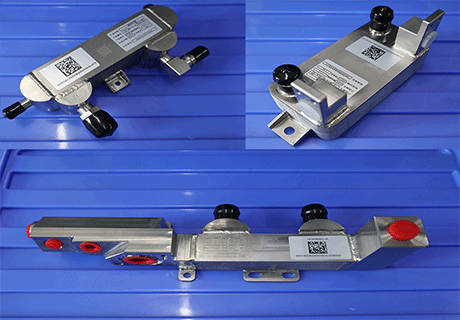

The hydrogen heater preheats the hydrogen that passes into the reactor, accelerates the start-up speed of the reactor, and then quickly starts the hydrogen fuel cell vehicle.

Effective control of cabin and electronic equipment temperature.

Ensure that the temperature of fuel and oil is stable and prevent overheating or undercooling from affecting engine performance and life.

Reduce the high temperature air temperature after supercharging to reduce the heat load of the engine and increase the power of the engine.

Shenshi Technology is committed to improving energy utilization efficiency through advanced heat transfer technology and promoting the development and application of clean energy. Products are widely used in the field of green power in solid oxide fuel cells (SOFC), supercritical carbon dioxide (SCO2) power generation systems, nuclear power plants.

With efficient heat transfer technology, Shen's technology helps the efficient production and safe storage and transportation of hydrogen energy, and promotes the sustainable development of green electricity. The products play a key role in hydrogen production, storage and transportation of hydrogen and hydrogen supply in the field of hydrogen energy.

Shen's products are mainly used in the field of aerospace cooling electronic equipment, environmental control system, to help improve the performance and reliability of aerospace equipment.

Shen Si Technology products are widely used in Marine engines and gas turbines in the field of powertrain, helping to improve the efficiency and performance of the system and maintain efficient operation.

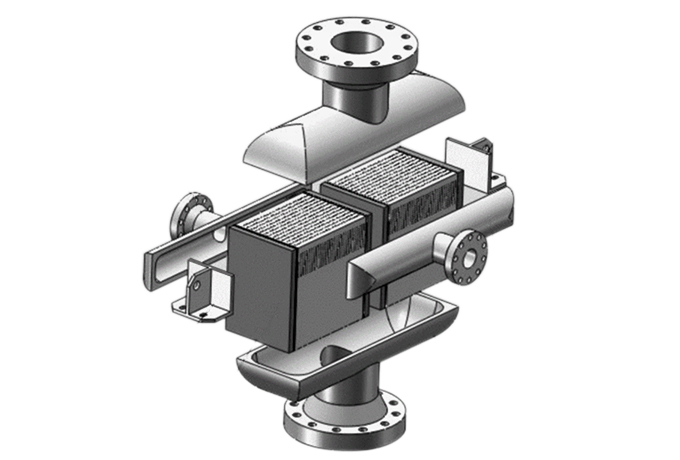

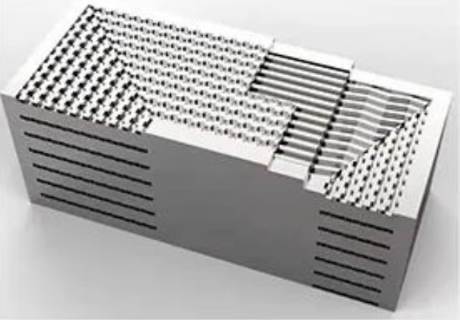

With the increasing exhaustion of energy and environmental deterioration, the development and utilization of efficient and clean new energy will become an important choice for energy development in the 21st century. Solid oxide fuel cell (SOFC) is an all-solid-state electrochemical power generation device that converts chemical energy in fuel and oxidizer directly into electrical energy. The energy conversion efficiency is high, which can reach about 60%. The generated heat for cogeneration efficiency can reach more than 80%, is currently the most cutting-edge, but also the most technically difficult new fuel cell, the world's developed countries generally regard it as a strategic reserve technology. The FPHE printed plate type micro-channel heat exchanger developed by Shen's technology has been applied in many cases on SOFC and SOEC systems. In recent years, the company has continued to make efforts in this field, polishing product quality and expanding market share.

Shen's Technology and Weichai cooperated to develop the Marine titanium alloy intercooler and applied it to the Marine power system. The titanium alloy intercooler developed by Shen's technology adopts plate-fin structure, and the heat exchanger core is formed by vacuum diffusion welding. The principle is to apply appropriate pressure and temperature to several layers of metal sheets of different thicknesses after the flow path and shape processing, so that the metal surface is fully combined. The core made by this welding method has the advantages of no joint, no weld, no any other type of potential fault point, and its strength after welding can reach more than 95% of the base material to ensure the excellent performance of the product.

Shenshi Technology has provided nearly 10,000 hydrogen preheaters to leading automotive hydrogen fuel cell system manufacturers such as Remodeling, Guohong, Bosch, and Yihuatong. The reactor hydrogen heater is an important part of hydrogen fuel cell vehicles. In the north and cold regions, the hydrogen heater can heat the hydrogen passed into the reactor, solve the cold start problem in cold regions, and the waste heat generated by the reactor can also be used

Through regular preventive maintenance, potential problems can be discovered and resolved in a timely manner, extending the service life of the heat exchanger, maintaining stable performance, improving energy efficiency, reducing the risk of failure, and ensuring that the heat exchanger is always in the best condition.

During operation, impurities such as sediment and scale may accumulate in the internal channel of the heat exchanger, resulting in a decrease in heat transfer efficiency, affecting equipment performance and energy efficiency, and thus affecting production efficiency and equipment life. Shenshi Technology will recommend cleaning methods for heat exchangers according to the equipment and actual application to keep the equipment in good running condition.

Shen's Technology professional service team is on standby to quickly and accurately identify the problem for you and provide the best solution. Not only to solve the current problem, we also want to help you prevent potential risks through professional services.

Additional services are the value-added protection Shenshi Technology provides for you in addition to the basic services. Shen's Technology will use accurate testing technology to comprehensively inspect equipment components and check the risk of leakage. Based on the test results, we will provide advice on the best measures to help you resume production.