Integrates multiple microchannel reaction units into a compact reaction device.

Fine Chemical Industry

Microchemical Solutions

Products

- Spiral Tube Reactor

Achieves efficient mixing and heat transfer through the rotating flow inside the spiral tube.

Microchannel MixerUtilizes fluid dynamics effects within microchannels to achieve rapid and uniform mixing.

Laboratory-Scale ReactorA miniaturized reaction device suitable for laboratory research.

Micro Continuous Flow Skid SystemAn integrated reaction device combining microreaction technology with continuous flow technology.

Industry

Pharmaceuticals

Used in drug synthesis, catalytic reactions, crystal engineering, and purification. It offers high efficiency, speed, precision, and strong controllability, accelerating new drug development and improving production efficiency.

Petrochemicals

Features efficient heat and mass transfer characteristics, optimizing key processes such as heavy oil cracking. Supports the development of new processes and drives continuous, efficient, and cost-effective petrochemical production.

Agrochemicals

Enhances synthesis efficiency and product quality, accelerates the development of new agrochemicals, and promotes continuous and automated production, reducing costs.

Dyes and Pigments

Optimizes the dye synthesis process, enhances color mixing uniformity, supports new dye development, and improves the continuity and efficiency of dye production.

Fragrances

Efficiently synthesizes complex aromatic components, precisely blends fragrance ratios, accelerates new product development, and achieves high-efficiency automation in production processes.

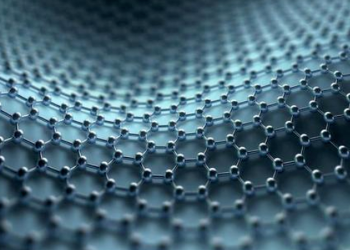

New Materials

Facilitates the synthesis of nanomaterials, enhances the uniform mixing of material components, supports rapid development of new materials, and promotes the continuous and scalable production of new materials.

Case Story

- 微化工

Service

Download

Product Introduction

- Microcontinuous flow product sample