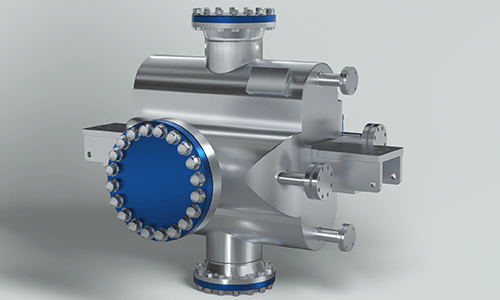

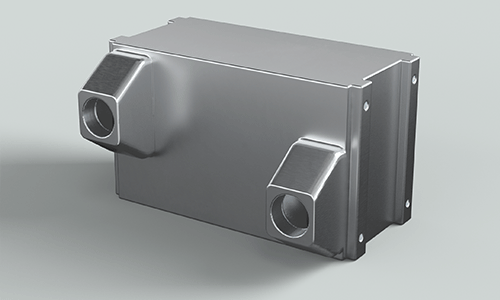

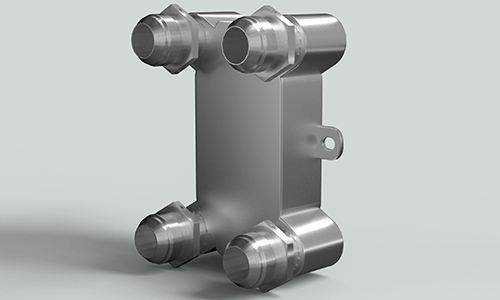

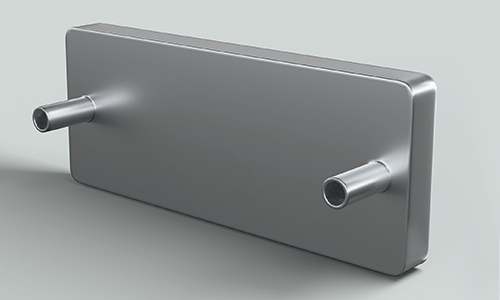

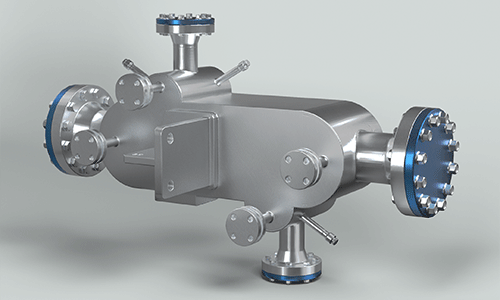

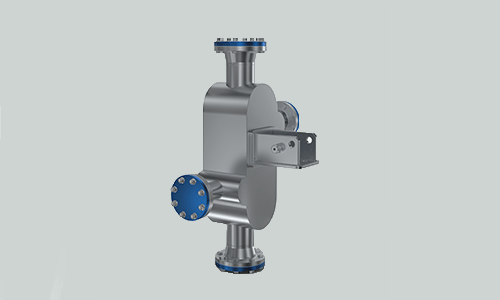

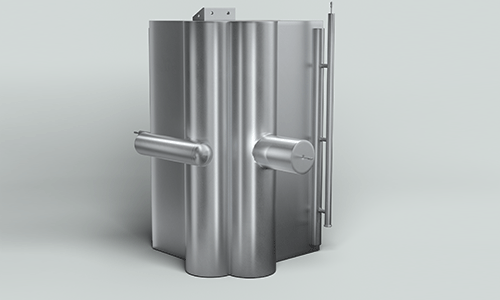

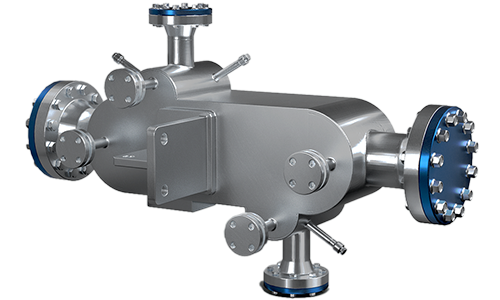

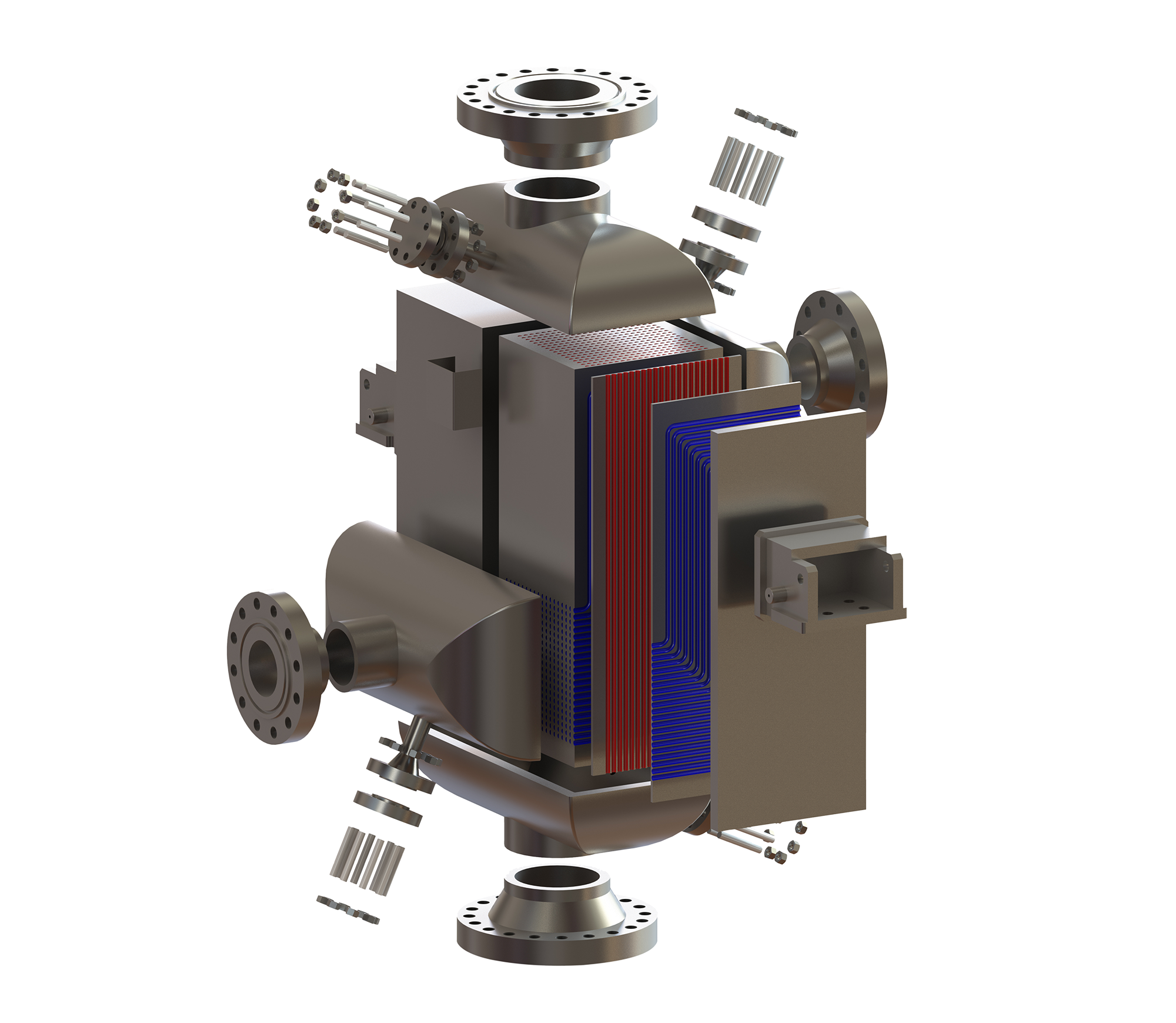

Printed Circuit Plate Heat Exchanger (PCHE)

- Technical Characteristics

- Solution

- Related Products

- Related Industry

- Case Story

- Shen's Service

- File Download

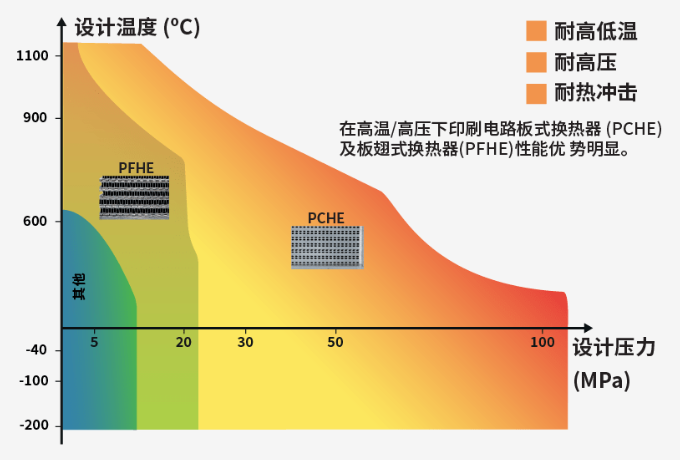

技术特点

Small Size

Efficient Heat Transfer

High Pressure Resistance

Strong Reliability

Widely Used

Shen's Solution

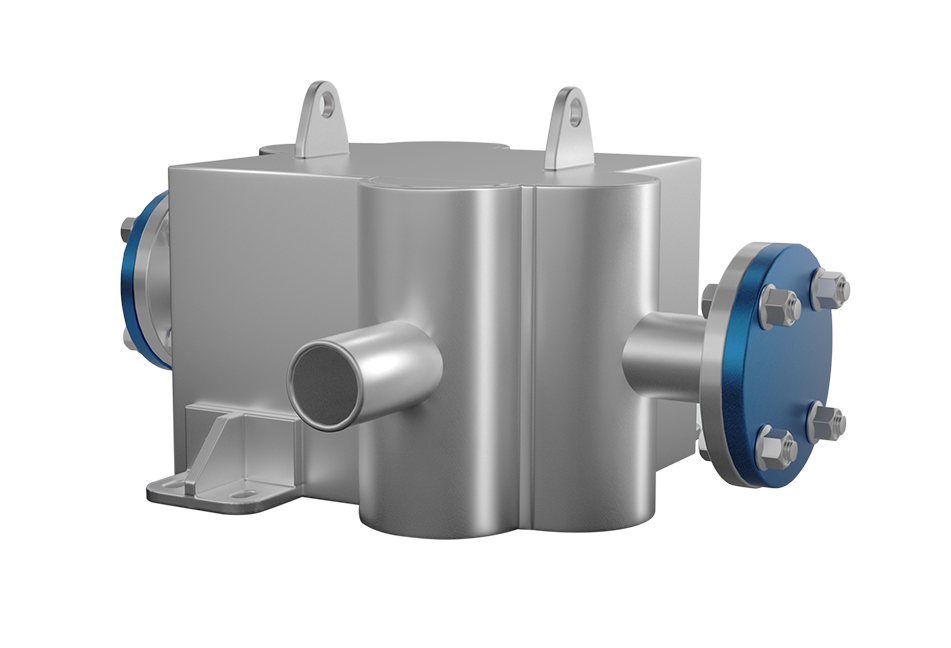

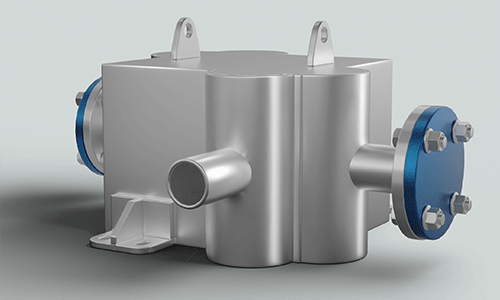

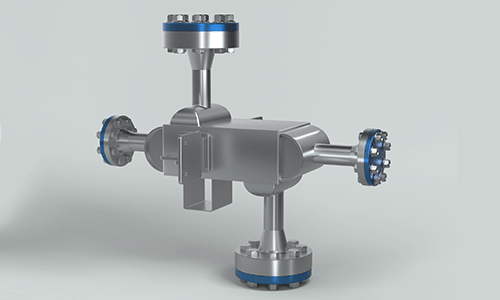

Related Products

- Heater

Operating at high pressure and temperature, it can be used in a variety of industrial processes and power generation applications

RegeneratorIt is used to reheat carbon dioxide after expansion, raising its temperature before entering the next stage of the cycle.

CoolerReduce the temperature of CO₂ to its required operating range.

Waste Heat Recovery Heat ExchangerIt is used to capture and utilize excess heat generated during the operation of nuclear power plants, helping to improve the overall efficiency of nuclear power plants.

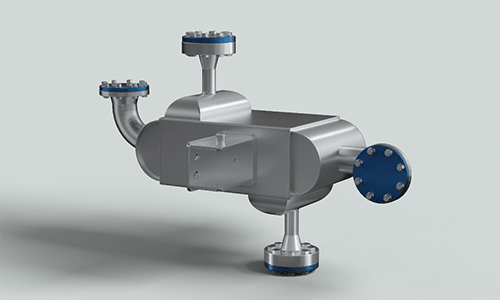

- Intercooler

The natural gas and refrigerant heat exchange, cooling, to ensure the safety of the transportation process.

Compressor AftercoolerCooling system for natural gas compressors to control the temperature of compressed natural gas

BOG Heat ExchangerBOG processing systems used in LNG ships and LNG receiving stations can reliquify LNG that is volatilized due to rising temperatures during transmission and reduce natural gas losses

Wet Air CoolerIt is used in the cooling system to achieve the cooling of natural gas through the heat exchange of water or seawater with natural gas.

High Pressure GasifierUsed in FGSS high-pressure systems, the general pressure is 300Bar, to gasify natural gas.

- Air Heater

The air heater heats the air entering the hydrogen production system to the reaction temperature.

Steam GeneratorThe steam generator vaporizes the feed water into gas, which enters the SOEC reactor to produce hydrogen.

Hydrogen ReformerThe hydrogen reformer reforms and exchanges heat with fuels such as methanol and water to produce hydrogen.

Hydrogen Liquefaction Heat ExchangerThe hydrogen liquefaction plate-fin heat exchanger exchanges heat between hydrogen and gases such as nitrogen, cooling it to a liquid state.

Fuel Cell Hydrogen PreheaterThe hydrogen heater preheats the hydrogen entering the stack, accelerating stack startup and enabling rapid start of hydrogen fuel cell vehicles.

Hydrogen Compressor CoolerThe hydrogen compressor cooler primarily cools compressed hydrogen, preventing dangers caused by excessively high compression temperatures.

Hydrogen Station Hydrogen CoolerThe hydrogen station cooler lowers the temperature of hydrogen during refueling, ensuring safe refueling.

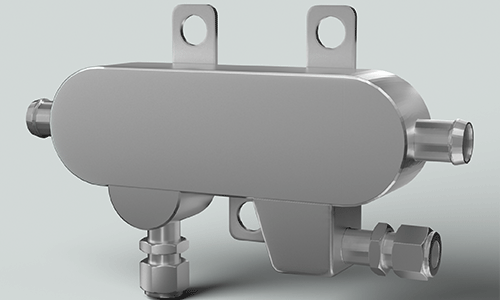

- Evaporator/Condenser

Effectively regulates the temperature of the cabin and electronic equipment.

Fuel and Oil Heat ExchangerEnsures the temperature stability of fuel and oil, preventing the impact of overheating or overcooling on engine performance and longevity.

Electronics CoolingResponsible for the heat exchange between the coolant of the liquid cooling subsystem and the coolant of the various regional liquid cooling subsystems.

Cold PlateConducts and dissipates the heat generated by electronic equipment, keeping the equipment temperature within an appropriate range.

- 性能加热器

The high temperature air temperature after pressurization is reduced to reduce the heat load of the gas turbine, increase the intake gas, and thus increase the power of the gas turbine.

- Carburetor

When gas is needed, it is heated to vaporize, such as LNG carburetor, ammonia carburetor, etc.

Liquefaction Heat ExchangerTransfer heat between compressor terminal exhaust and refrigerant to liquefy the gas.

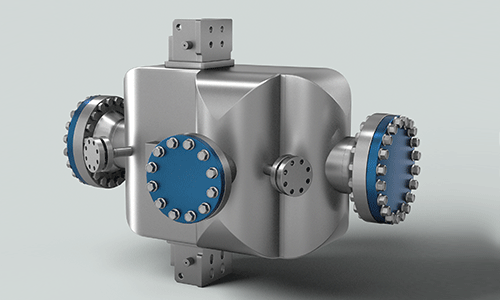

- Microchannel Reactor

A miniaturized reaction device that integrates multiple microchannel reaction units in one body.

Spiral Tube ReactorEfficient mixing and heat transfer are achieved by rotating flow in a spiral tube.

微通道混合器利用微通道内的流体力学效应实现快速均匀混合。

实验室级反应装置适用于实验室研究的微型化反应装置。

微连续流撬装系统将微反应技术和连续流技术相结合的集成化反应装置。

Related Industry

Shen's Technology is dedicated to enhancing energy efficiency through advanced heat exchange technology, promoting the development and application of clean energy. Our products are widely used in the field of green electricity, including solid oxide fuel cells (SOFC), supercritical carbon dioxide (SCO2) power generation systems, and nuclear power plants.

Shen's Technology's products are widely used in the marine and offshore sector, including floating storage and regasification units (FSRU), floating liquefied natural gas (FLNG) units, floating production storage and offloading (FPSO) units, and oil and gas platforms.

Shen's Technology leverages efficient heat exchange technology to facilitate the efficient production and safe storage and transportation of hydrogen energy, promoting the sustainable development of green electricity. Our products play a key role in hydrogen production, storage, and supply.

Shen's Technology products are primarily used in the aerospace field for cooling electronic equipment and environmental control systems, helping to enhance the performance and reliability of aerospace equipment.

Shen's Technology products are widely used in the powertrain field, including marine engines and gas turbines, helping to improve system efficiency and performance for sustained high-efficiency operation.

Shen's Technology products are used in the industrial gases sector for carbon capture and storage (CCUS), re-liquefaction systems, gas separation, rare gas extraction, and gas energy storage and power generation, contributing to the greening and efficiency of the industrial gases industry.

Shen's Technology enhances production efficiency and product quality in the fine chemicals industry through innovative technology, aiding the efficient manufacturing of various fine chemical products. Our products are widely used in pharmaceuticals, petrochemicals, pesticides, dyes, fragrances, and new materials industries.

Case Story

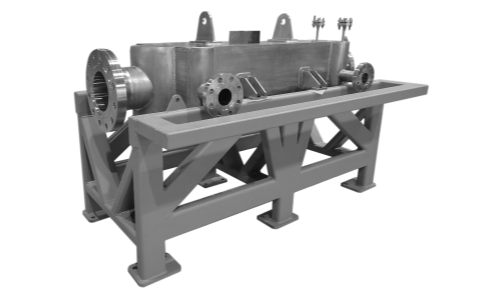

PCHE Heat Exchanger in LNG Field

In October 2020, the microchannel compact high-efficiency heat exchanger (PCHE) engineering prototype, jointly developed by CNOOC Gas & Power Group Co., Ltd., CNOOC (China) Co., Ltd. Shanghai Branch, and Hangzhou Shenshi Energy Conservation Technology Co., Ltd., passed the achievement appraisal of the China Machinery Industry Federation. This development filled a domestic gap, reached the international advanced level overall, and can be applied in the marine oil and gas/LNG and related fields.

Natural Gas Cooler

At the end of 2021, the first set of domestically produced large-scale high-efficiency compact wet natural gas coolers (PCHE), jointly developed by Hangzhou Shenshi Energy Conservation Technology Co., Ltd. and CNOOC Gas & Power Group Co., Ltd., was officially delivered after passing CCS certification. It was installed on a CEPA platform in a gas field of CNOOC (China) East China Sea Xihu Oil & Gas Operation Company. This marked the mass production of large-scale printed circuit heat exchangers by Hangzhou Shenshi in the marine engineering field.

Compressor Aftercooler

In December 2023, Shenshi Technology successfully developed and delivered three ultra-large dry gas compressor aftercoolers (PCHE) with a power of up to 12MW, further increasing the production capacity of an offshore oil and gas platform in the East China Sea. In the natural gas processing system of offshore oil and gas platforms, dry gas compressor aftercoolers play an indispensable role. The natural gas extracted from offshore oil and gas platforms needs to be quickly, efficiently, safely, and stably transported through subsea pipelines to onshore storage facilities, generally using pressurization to increase gas density and reduce storage volume.

Shen's Service

Preventive Maintenance

Regular preventive maintenance can identify and resolve potential issues in a timely manner, extending the lifespan of the heat exchanger, maintaining stable performance, improving energy efficiency, reducing the risk of failure, and ensuring the heat exchanger is always in optimal condition.

Cleaning

During operation, the internal channels of the heat exchanger may accumulate deposits, scale, and other impurities, leading to a decrease in heat transfer efficiency, affecting equipment performance and energy efficiency, and thereby impacting production efficiency and equipment lifespan. Shenshi Technology will recommend cleaning methods for your heat exchanger based on the equipment and actual application conditions to maintain optimal operational status.

Service Support

The professional service team at Shenshi Technology is always on standby to quickly and accurately identify the problem and provide the best solution. Beyond resolving the current issue, we aim to help you prevent potential risks through our professional services.

Additional Services

Additional services are the value-added assurance that Shenshi Technology provides beyond basic services. We use precise testing techniques to comprehensively inspect equipment components and check for leakage risks. Based on the test results, we will offer recommendations for the best measures to help you restore production.

File Download

Product Manual

- Microchannel Heat Exchanger Product Sample