Reduces the temperature of high-temperature air after compression to lower the thermal load on the gas turbine, increase the intake volume, and subsequently enhance the power of the gas turbine.

Powertrain

Shen's Technology Solutions

Related Products

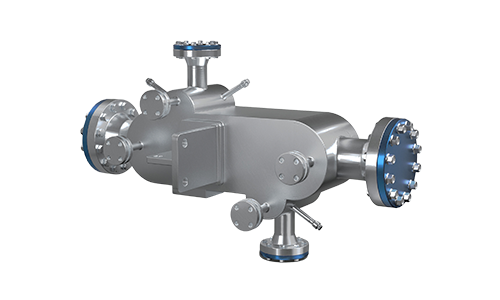

- Titanium Alloy Intercooler

Reduce the high temperature air temperature after supercharging to reduce the heat load of the engine and increase the power of the engine.

- Titanium Alloy Intercooler (Intercooler)

Reduces the temperature of high-temperature air after compression to lower the engine's thermal load and increase the engine's power.

Related Industry

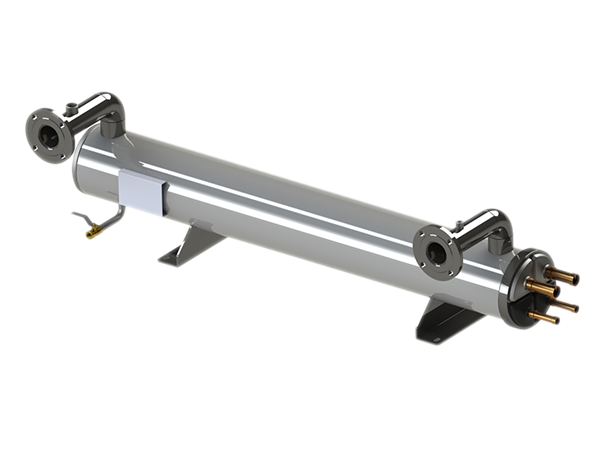

Effectively transfers heat between different fluid flows within the engine system, helping to optimize engine performance and fuel consumption, extend its lifespan, and reduce maintenance needs.

Effectively cools turbine blades and other hot components by transferring heat to the coolant, thereby improving turbine efficiency and lifespan.

Related Service

Preventive Maintenance

Regular preventive maintenance helps identify and resolve potential issues in a timely manner, extending the lifespan of the heat exchanger, maintaining stable performance, improving efficiency, reducing the risk of failures, and ensuring that the heat exchanger remains in optimal condition.

Cleaning

During operation, the internal channels of the heat exchanger may accumulate sediments, scale, and other impurities, leading to reduced heat transfer efficiency and impacting equipment performance and energy efficiency, which in turn affects production efficiency and equipment lifespan. Shen's Technology will recommend cleaning methods for the heat exchanger based on the equipment and actual application conditions to keep the equipment in good working order.

Service Support

The professional service team at Shen's Technology is always on standby to quickly and accurately identify issues and provide the best solutions. Not only do we address current problems, but we also aim to help you prevent potential risks through our professional services.

Additional Services

Additional services are value-added protections provided by Shen's Technology beyond the basic services. Shen's Technology will use precise testing techniques to comprehensively inspect equipment components and check for leakage risks. Based on the test results, we will offer recommendations for the best measures to help you resume production.

File Download

Product Manual

- Product catalog of coaxial tube/shell and tube heat exchangers

- Microchannel heat exchanger product sample