Zhejiang micro Zhiyuan Energy Technology Co., LTD

Zhejiang Micro Zhiyuan Energy Technology Co., Ltd. is a wholly-owned subsidiary of the Group engaged in micro chemical business, located in the town of Medicine Port, Qiantang District, Hangzhou. It is committed to the research and development of micro continuous flow chemical process and the engineering installation service of complete sets of system equipment in the fields of pharmaceutical, pesticide, dye and other fine chemicals. Micro-channel reactor, micro-channel mixer, micro-channel heat exchanger, tube reactor, etc.

Home / hzwzy

Production Equipment

The company is mainly committed to the development and manufacture of advanced microchemical complete sets of equipment; Provide turnkey projects from experimental development to industrial production in the field of medicine and chemical industry. Compared with the traditional chemical process, the most important thing for microchemical technology is to research and develop the reactor and rapid reaction process conditions suitable for microreaction system.t has large specific surface area, high transfer rate, short contact time and less by-products; Fast, direct amplification; Easy to operate; Green production, high safety features.

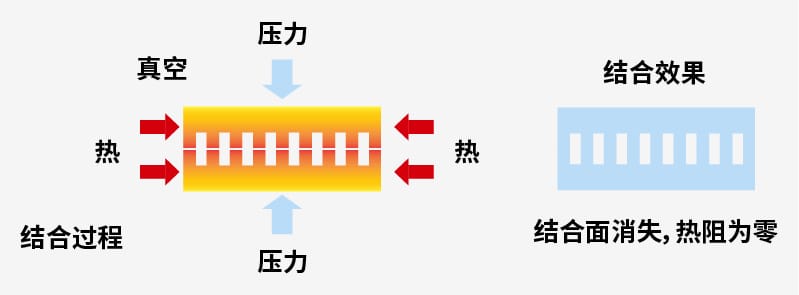

Diffusion Welding Technique

The principle is that a number of layers of different thickness of the metal sheet through the flow channel and shape processing, in the vacuum state to apply appropriate pressure and temperature, so that the metal surface is fully combined. The heat exchanger core made of diffusion welding technology has the advantages of no joint, no weld, no any other type of potential fault point, and its strength after welding can reach more than 95% of the base material to ensure the excellent performance of the product.

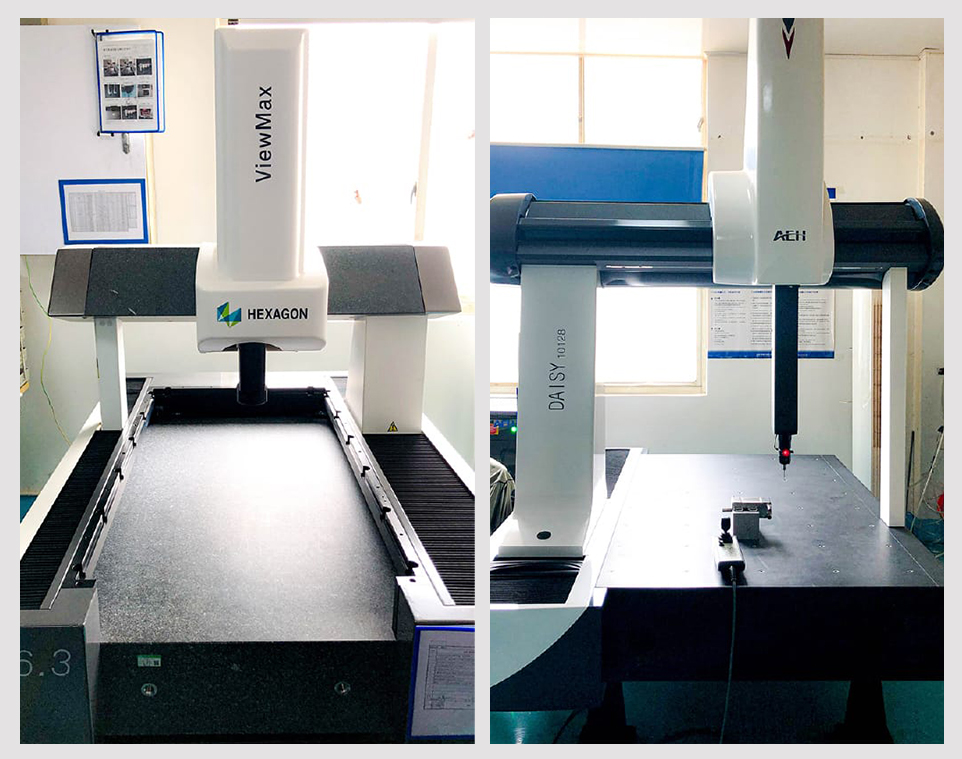

Quality Assurance

Hangzhou Micro control with "commitment to quality and safety" as the core concept, from product quality to manufacturing industry, and then to employee safety, layers of control, strict management. We strictly enforce the highest standards of health and safety. Hangzhou Micro control always puts customers first.

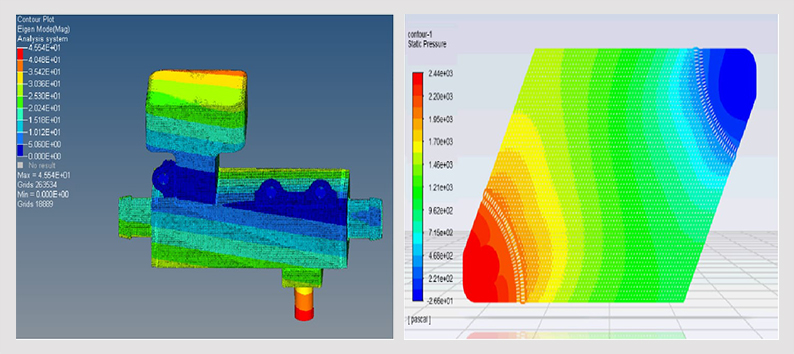

Design Calculation

According to the accumulated experience of calculation, simulation and test of micro-channel and plate-fin products for many years, the calculation formula and correction coefficient are fitted to ensure the accuracy of the design, and the unique design method of heat exchanger is formed, which can provide reasonable and feasible design schemes according to different environment, appearance and heat transfer needs.

Application Case

1. Jiangsu Yangnong Group Co., LTD., with an annual throughput of 18,000 pesticide intermediates (Jiangsu Yangnong Chemical's original production plant with an annual output of 7,000 tons of pesticide intermediates covers an area of about 150㎡ and a building area of about 300㎡). The workshop needs three layers, the total height of the device is about 18 meters, and the land area is only about 35 square meters after changing to Shenshi micro-chemical reaction system, and the height of the equipment is not more than 2 meters. The safety factor of production is improved while the footprint is reduced, and the reaction is changed from intermittent reaction to continuous reaction and automatic control is adopted to improve the production efficiency. Completely subvert the original reaction conditions, and annual energy consumption can save more than 1 million costs);2. 5000t pesticide intermediates project of a Zhejiang Chemical Group (the project basically realized the whole process automation from the traditional batch reactor to the current micro-channel continuous flow production, and the whole process was realized in the micro-channel, which greatly improved the output, safety and other aspects, and greatly reduced the emission of odor gases. The yield of continuous flow process is 14% higher than that of kettle equipment.3. 500t perfluorohexanone project in a Shanghai Co., LTD. (The project took one year from inception to landing, the agreement between the industrialization data and the pilot data was close to 99%, basically no amplification effect, and the workshop was reduced from the original eight people to three people, saving a lot of labor costs);4. A pharmaceutical company in Zhejiang Province, hydrogenation project (using continuous flow process, system feed accuracy, temperature control and the entire reaction residence time have been significantly improved, the device covers a small area, can be continuously operated, and the entire process operation is simpler and safer);5. A university in Zhejiang Province, hydrogen production project (miniature hydrogen production reactor, methanol and water vaporized into the reactor at (280℃) for catalytic hydrogen production, volume 100mm * 100mm * 100mm per hour 1 kg hydrogen production (can supply 40kw fuel cell consumption).

Dominant Service

Wide selection range:

316L, duplex steel, Ha C276, TA10, Zr, silicon carbide and other different material selection productdiversification:

Micro-channel mixer, micro-channel heat exchanger, micro-channel reactor, micro-reaction complete set,tubular reactor;High flexibility:

Can be multi-feed, zone temperature control. At the same time can be used alone, can also be used in series;Nozzle size standardization or nozzle customization services can be provided:

Standard inch or metric interface to provide customized services for easy connection to other equipment systems;Can provide product customization services:

To provide customers with special design and customized services, to meet the needs of customers;Service hotline

0571-64515888