In the CO2 compressor cycle, the economizer is used to further cool the refrigerant exiting the evaporator (i.e., subcooling) to improve the overall system efficiency.

Industrial Gas

Industrial Gas Solutions

Related Products

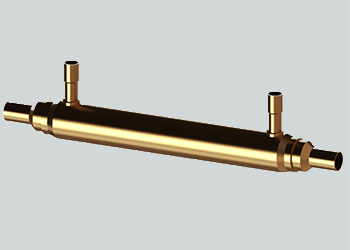

- SCO2 Heat Exchanger

In ORC systems, used for heat exchange with supercritical CO2 to improve system efficiency.

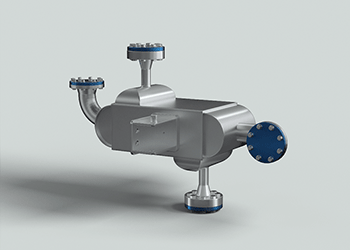

- Liquefaction Heat Exchanger

The liquefaction heat exchanger cools and liquefies various gases, such as oxygen, hydrogen, helium, etc.

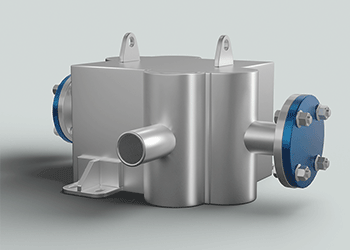

VaporizerIn industrial production, a vaporizer exchanges heat to vaporize various low-temperature liquids.

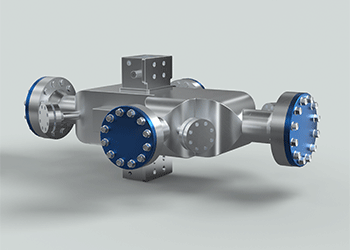

- Air Separation Heat Exchanger

The air separation heat exchanger separates various gases based on their different boiling points.

Related Industry

Shenshi Technology provides SCO2 heat exchangers and CO2 economizers for carbon capture, with options including highly efficient compact microchannel heat exchangers and more economical coaxial pipe heat exchangers.

Shenshi Technology offers thermal management solutions for reliquefaction systems, providing intercoolers for compressors, liquefaction heat exchangers and economizers for cooling systems, as well as vaporizers for downstream applications.

Shenshi Technology provides thermal management solutions for gas separation. The company's developed compressor intercoolers and air separation coolers are compact and highly efficient, effectively reducing temperature rise caused by gas compression and improving gas separation efficiency.

Related Service

Preventive Maintenance

Regular preventive maintenance can help identify and address potential issues early, extend the lifespan of the heat exchanger, maintain stable performance, improve energy efficiency, reduce the risk of failures, and ensure the heat exchanger is always in optimal condition.

Cleaning

During operation, impurities such as sediments and scale can accumulate inside the heat exchanger's channels, reducing heat transfer efficiency, impacting equipment performance and energy efficiency, and consequently affecting production efficiency and equipment lifespan. Shenshi Technology will recommend cleaning methods based on the equipment and its application to keep the equipment in good operating condition.

Service Support

The Shenshi Technology professional service team is always on standby to quickly and accurately identify problems and provide the best solutions. We aim not only to resolve current issues but also to help you prevent potential risks through our professional services.

Additional Services

Additional services are value-added guarantees provided by Shenshi Technology beyond basic services. We use precise testing techniques to thoroughly inspect equipment components and check for leak risks. Based on the test results, we will offer recommendations for the best measures to help you resume production.

File Download

Product Manual

- Product catalog of coaxial tube/shell and tube heat exchangers

- Microchannel heat exchanger product sample