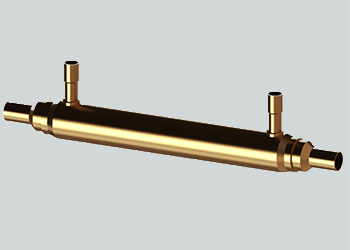

In ORC system, it is used for heat transfer of supercritical CO2 to improve system efficiency.

CCUS

The core of CCUS technology is its comprehensive management of greenhouse gases - from capture at source to innovative use and safe storage. This process not only reduces the amount of carbon dioxide in the atmosphere, but also opens up new ways to recycle resources. Globally, CCUS is emerging as one of the key technologies to achieve carbon neutrality. From cement production to steel manufacturing, from oil and gas processing to thermal power generation, CCUS technology is applied across multiple industrial sectors, providing practical solutions for deep emissions reductions.CCUS refers to a technology that can be effectively used to capture carbon dioxide. Carbon dioxide emitted in the production process can be captured, stored, or purified and put into the new production process for recycling. So far, it is the only means that can significantly reduce greenhouse gas emissions in industrial processes, and it is also one of the key technologies to deal with global climate change.

Home / CCUS

Shen's Technology Solutions

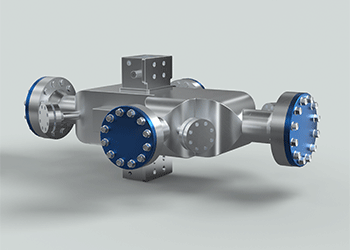

Shen's Technology provides thermal management solutions for CCUS. Shen's SCO2 heat exchangers and CO2 economizers can effectively improve the efficiency of CCUS system, increase CO2 production, and provide help for green sustainability.

Related Products

- CO2 Economizer

In the cycle of the CO2 compressor, the economizer is used to further cool (i.e. supercool) the refrigerant flowing out of the evaporator to improve the efficiency of the entire system.

Related Industry

SCO2 Power Generation

CCUS captures and stores CO2, which can be used in SCO2 Rankine cycle power generation to improve system efficiency and reduce carbon emissions.

ORC Waste Heat Recovery

The ORC system uses SCO2 as the heat transfer medium, which has high economic value.

File Download

Product Manual

- Product catalog of coaxial tube/shell and tube heat exchangers

- Microchannel heat exchanger product sample

Service hotline

0571-64515888