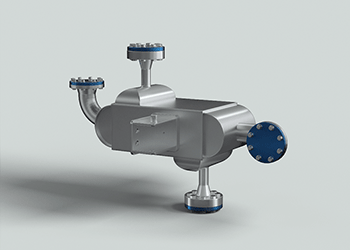

Transfer heat between compressor terminal exhaust and refrigerant to liquefy the gas.

Reliquefaction System

The reliquefaction of industrial gases is mainly to liquefy easily liquefied gases such as ethane, ammonia and LNG, which have high boiling points and are convenient for transportation.The reliquefaction system usually consists of the following main components: Compressor: The compressor is one of the key components of the reliquefaction system. It compresses a gas to a temperature and pressure above the point of liquefaction by increasing its pressure. Coolers: Coolers are used to reduce the temperature of compressed gas to a temperature below the liquefaction point. Coolers usually use coolant or cooling water to absorb heat and cool gas. Pressure reducing valve: The pressure reducing valve is used to control the pressure of compressed gas so that it reaches the pressure below the liquefaction point after passing through the pressure reducing valve. Separators: Separators are used to separate liquid gas from unliquefied gas. It collects the liquid gas by gravity or other separation methods and expels it from the system. Storage tanks: Storage tanks are used to store liquid gases for ready supply to industrial processes where needed.

Home / Reliquefaction system

Reliquefaction Solutions

Shen Technology provides thermal management solutions for reliquefaction systems, intercoolers for compressors, liquefaction heat exchangers and economizers for cooling systems, and carburetors for back-end applications.

Related Products

- Carburetor

When gas is needed, it is heated to vaporize, such as LNG carburetor, ammonia carburetor, etc.

Related Industry

Gas Liquefaction

Suitable for liquefying industrial gases such as hydrogen, LNG, propane, and ammonia for convenient transportation.

Cold Energy Utilization

During the gasification of liquids, a significant amount of cold energy is released. Shen's Technology heat exchangers can use this energy to produce other gas products or generate electricity.

Compressor Intercooling

At hydrogen refueling stations, hydrogen compressors compress hydrogen to tens of MPa for storage. Heat exchangers cool the high temperatures generated by the compressors to ensure safety.

File Download

Product Manual

- Microchannel Heat Exchanger Product Sample

Service hotline

0571-64515888